HIGH VOLTAGE INSULATION COATING

Solution

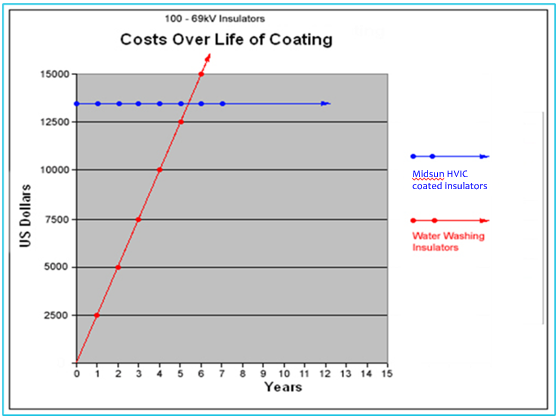

Reliable, Cost Effective & Easy Application. For a long-term, cost-effective, and a reliable product CCS uses Midsun High Voltage Insulator Coating.

Midsun HVIC silicone coating provides a maintenance-reduced system that can prevent excessive current leakage, tracking, and flashovers on any type of high-voltage insulators.

Midsun HVIC silicone is not affected by UV light, temperature, corrosive environments, or ATH pitting from dry band arcing. The coating is also hydrophobic (water repellent), so contaminants cannot solidify into a film over the surface. This coating application is a long-term solution to flashover problems

Why?

Near maintenance free.

Not affected by UV light, temperature, corrosive environments, or ATH pitting from dry band arcing.

Highly water repellent – contaminants cannot film over the surface.

Excellent dielectric properties.

Can be applied ENERGIZED or de-energized

Protects against salt, coal dust, cement, sugar cane, carbon, fly ash, animal droppings, cooling towers, etc.

Eliminates or reduces

Regular insulator washing.

Periodic re-application of grease.

Replacement of components damaged by flashovers.

Repair silicone sheds and rod damage on composite insulation systems.

How HVIC Works?

HVIC application at commissioning

Proactive solution in a highly contaminated area

This will significantly reduce the need for insulation washing

Reduce flashover related outages due to contamination

Energized HVIC application

We use the ONLY High Voltage Insulator Coating formulated for ENERGIZED applications.

Our HVIC Energized offers utility companies the opportunity to perform quality maintenance for pollution induced outages, without having to experience costly shut downs.

Reduces

Costly maintenance shutdowns.

Unnecessary wear and tear on system back up units.

Reliance on peak loading generation.

Independent Power Producer contract fines.

High resistance to extreme temperatures, salt and corrosive environments

Not affected by UV light, corona discharge or chemical contaminants

Mitigate pollution caused outages

Costly maintenance shutdowns.

Unnecessary wear and tear on system back up units.

Reliance on peak loading generation.

Independent Power Producer contract fines.

High resistance to extreme temperatures, salt and corrosive environments

Not affected by UV light, corona discharge or chemical contaminants

Mitigate pollution caused outages

HVIC Applications

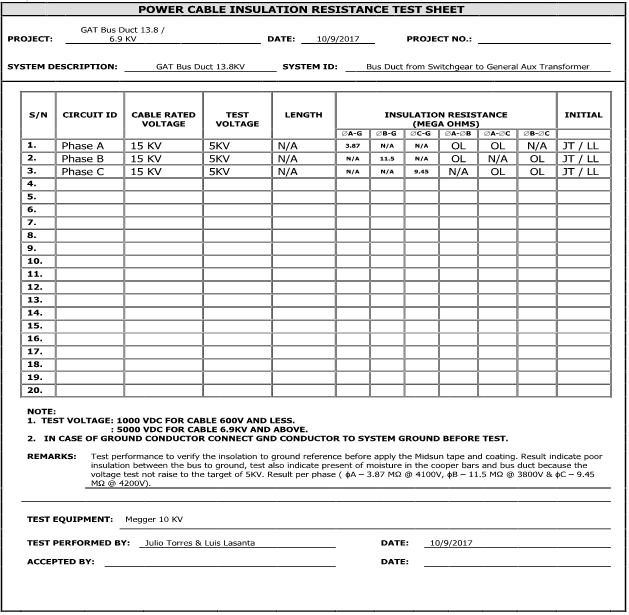

CCS bus duct maintenance helps utilities increase insulation resistance. CCS removes bus and replaces commonly used plastorsol cover up with higher insulating product and seals it with a High Voltage Coating.

This procedure prevents any moisture penetration which will lower resistance and deteriorate insulated cover up

Bus duct insulation resistance BEFORE Fuse Tape & HVIC application

Bus duct insulation resistance AFTER Fuse Tape & HVIC application